Case Study 005

Client:

Area Size:

2.53 ha

Timeline:

0.3 Days

Product:

SuppressX

Kanmantoo Bluestone Quarry

Stockpile Dust Suppression

Find out how we did it

Client:

Area Size:

2.53 ha

Timeline:

0.3 Days

Product:

SuppressX

Find out how we did it

Kanmantoo Bluestone Quarry

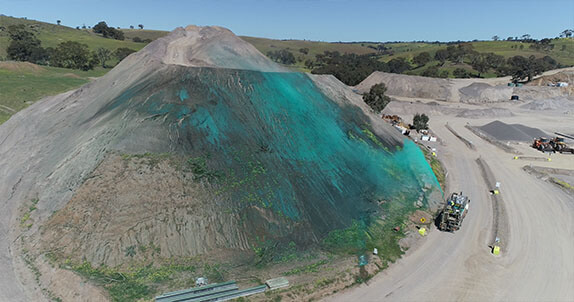

In 2018, Bluestone Quarry located South East of South Australia, was experiencing vast dust issues from an onsite, overburden stockpile – this prompted communication with Erizon concerning a durable, wind and rain resistant, dust suppressant. Due to the expected South Westerly winds projected to sandblast dust from the stockpile into the valley below, the issue required a rapid response.

Erizon was able to leave a lasting impression by successfully meeting the site requirements, and therefore were contacted for a second time in 2019, to provide dust management on the new stockpile deposits.

Scroll to see more

Kanmantoo Bluestone Quarry

In September 2019, Erizon was approached by Hanson Heidelberg Cement Group, on behalf of Bluestone Quarry, to provide a dust suppression solution for their 2.53-hectare overburden stockpile. The client was seeking to minimise dust and stabilise soil before 87km/hr South Westerly winds were expected to shift across the area, potentially caring dust particles over the valley, and posing risks to local water systems and communities within the region.

The stockpile under examination had remained in operation after the initial application and therefore required a dust suppressant on the newly deposited stock. The anticipated environmental requirements would mirror the 2018 project; therefore, Erizon was familiar with the site area and conditions.

Upon initial inspection, Erizon’s environmental consultants discovered areas that weren’t covered with new stock and had maintained surface crust integrity from the previous application. As the dust suppressant remained stable on-site for an excess of 12 months, the team chose to use the same solution:

• SuppressX - Applied at 500 Litres per hectare

Scroll to see more

Kanmantoo Bluestone Quarry

SuppressX has been designed explicitly for non-trafficked areas, such as the Bluestone Quarry stockpile, and scientifically engineered to eliminate dust lift without changing or compromising the substrate beneath it. Upon application to the soil, SuppressX performs as a protective barrier over the substrate below to form an interconnected flexible crust, providing superior dust control and erosion protection. Drawing on cutting edge technologies; the SuppressX coating is an efficient and cost-effective approach to dust suppression, helping to resist erosive winds and rains.

Equipment:

Based on the pre-site drone mapping and analysis of the project topography, the Erizon team would be required to provide extensive coverage of the 2.53-hectare stockpile, using our mine site compliant HydroTruck with water cannon to hydraulically apply the solution effectively onto the substrate.

Their pure design, power, and speed eliminated the need to work on steep slopes and can provide fast and adequate coverage. The purpose-built trucks have built-in agitators within the holding tanks that consistently mix the product to ensure that an even application is hydraulically applied at a distance of 100m and boasts the ability to cover 50,000+ square meters per day.

Scroll to see more

Kanmantoo Bluestone Quarry

Erizon mobilised at the Kanmantoo Quarry site on the 26th of September 2019, to conduct the application of the SuppressX solution over 2.53-hectares of their overburden stockpile. The project involved, eliminating the prospect of extensive dust shifting off the peak of the stockpile and flowing into the valley below during expected high winds.

Due to the potential risks associated with the dust issue, Erizon moved promptly to undertake the project in one continuous application phase. The team underpinned this process with the knowledge and familiarity of the site acquired during the initial project execution completed in 2018.

Upon onsite inductions, and approval of plant and equipment safety checklists, works were successfully conducted and achieved within four hours of being on-site.

Scroll to see more

Kanmantoo Bluestone Quarry

Erizon recognised, weather challenges throughout the duration of the project with the following issues attended to promptly and efficiently.

Weather:

• Mild west northerly west, winds reaching up to 35 km/h, posed some challenges; however, the technicians were able to operate this in their favour with improvised positioning of plant and equipment, to withstand the winds and accurately apply the product onto the substrate.

• Although the mobilisation period was short and the environmental conditions provided a warm 26.9’ C day, a Heat and Fatigue Management Plan was implemented to ensure that breaks effectively operated. Technicians were also required to utilise their Personal Protective Equipment (PPE), designed to serve as a safeguard from ultraviolet radiation.

Scroll to see more

Kanmantoo Bluestone Quarry

The client inspected the area after the installation and was extremely pleased with the prompt application and ability for Erizon’s technicians to successfully Implement the product for the second consecutive year. Effective communication between both parties played a critical role in the efficiency that this project was able to maintain, throughout the entirety of the onsite mobilisation.

Scroll to see more

Enquire

Tell us about your project and get the best possible advice from our experts

Download

Download a PDF of this case study

Newsletter

Get the latest industry news as it happens